Low pressure plasmasystems

How is cold low pressure plasma technology applied?

Cold low pressure plasma is a cost-effective and environmentally friendly technique for processing a surface in polymer, metal, textile or ceramics on a microscopic level. While atmospheric plasma in the form of a plasma beam is used to very precisely treat parts of a surface, cold low-pressure plasma is suitable for larger surfaces at the same time. Surfaces of, for example, 3D models are treated completely with plasma in a closed vacuum chamber.

What is cold low pressure plasma used for?

These surface treatments with low-pressure plasma are extremely suitable for increasing or decreasing the surface tension. The technique is mainly used to bond or connect different materials and to change surface properties. For example, low-pressure plasma can be used for the precision cleaning of contaminated parts, the pre-treatment of surfaces for bonding of PTFE or the coating of plastic parts. These are just some of the many possibilities.

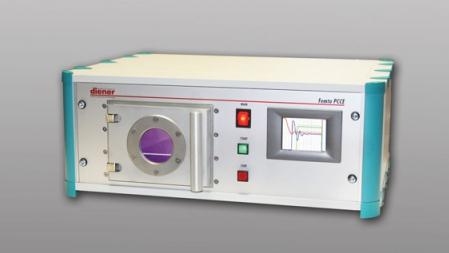

Discover our low pressure plasma systems

At SINVACON you will find a wide range of cold low pressure plasma systems. These are from the leading German brand Diener and are available in different sizes, configurations and with different controls. Do you want to evaluate this technology yourself or do you want to buy a cold low pressure plasma system right away? Both are possible. Please contact us to discuss the possibilities. Use the contact form or call +32(0)478 54 69 68.