Hydrophilic and hydrophobic plasma coating

Plasma coating, and in particular hydrophilic and hydrophobic coating, is a widely used technique in various sectors and industries. This technology therefore offers many advantages. For example, it is possible to use plasma technology to treat PDMS and other materials with a coating for a good connection and to strengthen the surface. Read on and discover more about this technology and systems at SINVACON, located in Gavere.

ultra clean surface

The surface is easier to moisten

the shear and tensile strength is 2 to 10 times higher

better adhesion (when bonding or soldering) of polymers, glass, metals and ceramic materials

What is plasma coating?

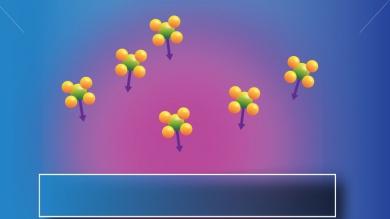

Plasma coating is one of the most exciting applications of plasma technology. First, the surface is cleaned or activated with plasma, breaking the bonds in the top layer of the surface. Activation or 'hygienic surface treatments' create new chemical functionalities with completely new properties. This does not affect the bulk properties of the underlying material. During the hydrophilic or hydrophobic plasma coating, a nanolayer polymer is formed on the entire surface of an object with a catheter. This layer forms a completely new surface. The coating is typically less than 1/100 of a human hair, colorless, odorless and does not affect the look and feel of the material.

Surface before treatment

Polymerisation

After treatment

Hydrophilic and hydrophobic coating

Plasma coatings can be divided into two types:

Hydrophilic plasma coating. A specific precursor is selected that forms a permanent coating with a very high surface energy. The coating is very thin, colorless and odorless and does not affect the material.

Hydrophobic plasma coatings. A specific precursor is selected that forms a permanent coating with a very low surface energy. Like the hydrophilic plasma coating, the coating is very thin, colorless and odorless and does not affect the material.

Before treatment

Surface after treatment

Applications of these techniques

Plasma coating offers enormous potential to enhance the functions of a material in various industries such as textile, food, consumer goods and many other applications. For example, hydrophilic plasma coating is used to apply a protective or barrier coating and to improve bio-molecular absorption. Hydrophobic plasma coating in turn takes place on textiles or medical devices, such as a catheter with a hydrophilic coating, and consumer electronics. The technique is also used for coating PDMS (polydimethylsiloxane). With PDMS, this coating is necessary to create a strong connection between surfaces.

Before treatment

Surface after treatment

Catheter with hydrophilic coating and other hygienic surface treatments in the medical sector

Hygienic surface treatments are a widely used method in the food sector, but also in the medical world. In this second sector, of course, there are also high hygiene requirements. Hygienic surface treatments by means of plasma ensure that these requirements can be met. For example, you can use a catheter with a hydrophilic coating to make it easier to moisten the surface. The catheter with hydrophilic coating is therefore easier to insert. A catheter with a hydrophilic coating is only one possible application of this technique. We would be happy to tell you more about the various options for a catheter with a hydrophilic coating if you contact us.

Let us know how we can help you

At SINVACON you will find a wide range of systems for plasma treatments, such as plasma coating, etchingand cleaning. For example, would you like to know more about a hydrophilic coating catheter or about hygienic surface treatments? Or do you want to have PDMS coated? Please contact us, we will also be happy to tell you more about the possibilities for rental and purchase. You can also outsource the handling of your materials to us. How can we help you? Let us know via the contact form or call +32(0)478 54 69 68.